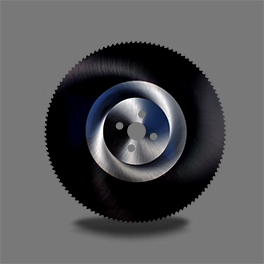

Metal HSS saw blade

Material:low carbon steel, medium carbon steel, high carbon steel Machine:various cold sawing machines Su

-

-

-

M2 or M35

-

Type: Circular saw blade

Application: Metal cutting

Material: M2 or M35

Coatings: TiN, TiCN, TiALN

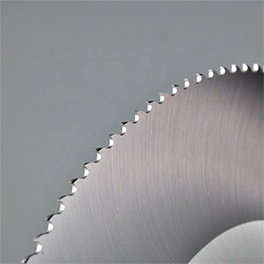

HSS circular saw blades of M2 or M35 quality with all PVD coatings can be provided, such as rough or toothed. Based on the material grade, it is recommended to change the angle of the teeth to suit your application of pipes, profiles, and solid black metal materials.

High speed steel M2-DMo5

High quality circular high-speed steel saw blade made of high-speed steel (5% molybdenum), suitable for cutting tensile strength of 500 N/mm ² And 800 N/mm ² Alloy steel between. These saw blades can be used for all saws to cut pipes, structures, and solid parts with a diameter or thickness of up to 200 millimeters.

High speed steel M35-Co5%

This is an ultra high speed steel that contains 5% cobalt in addition to the alloying elements already present in Dmo5. Ultra high speed steel (cobalt content 5%) circular saw suitable for cutting tensile strength exceeding 800 N/mm ² Steel and alloys. These blades are suitable for most saws and are used to cut pipes, structures, and solid parts with a diameter of up to 200 millimeters.

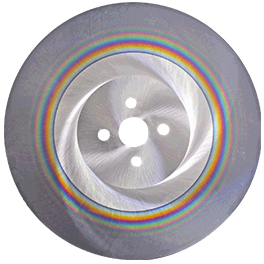

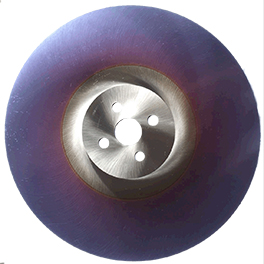

PVD coatings - TiN, TiCN, TiALN. These coatings are used to increase surface hardness, reduce friction, and allow for faster processing speeds. These benefits greatly increase the service life of the blade, thereby reducing the cost of each cutting.

Titanium nitride coating TiCN coating Aluminum nitride coating Steam oxidation

Steam oxidation

The standard hardness of these blades is 64-65 Rockwell hardness, suitable for universal cutting of all materials, including non-ferrous metals. The diameter ranges from 200 to 500 millimeters.

(Titanium Nitride) TiN

The color of Gold. This PVD coating increases the surface hardness to 2300-2500 (HV 0.05) and can be used on all materials, including stainless steel. A popular coating applied to tools to increase surface hardness, reduce friction, and maintain cutting edges.

(Titanium Carbonitride) TiCN

B light color/purple. The main advantage of this PVD coating is an increase in surface hardness of 3000 (HV 0.05). Similar to the characteristics of TiN, this coating has higher wear resistance and heat resistance, which can achieve higher cutting rates.

(Titanium aluminum nitride) TiAlN

Purple/gray. This PVD coating is an additional tough treatment that can achieve higher processing speeds with minimal cutting lubricants, specifically designed for stainless steel and other challenging applications. Its reduced thermal conductivity makes it the best coating for use at high temperatures or dry cutting.

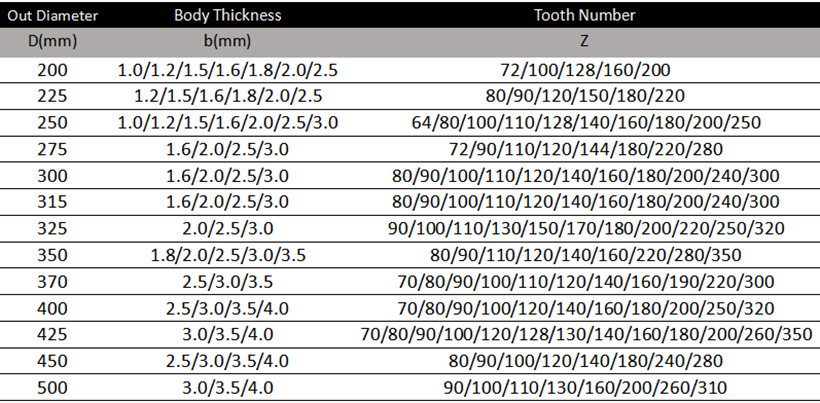

Product parameters:

Note: Customizable according to customer requirements.