Woodworking circular saw blade

Application:multirippingMachine:multiripping machineMaterial:softwood and hardwood at max 15% humidity rate

Application: multiripping

Machine: multiripping machine

Material: softwood and hardwood at max. 15% humidity rate.

|

Outer diameter D (mm) |

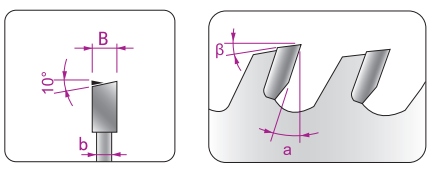

Tooth Width B (mm) |

Body Thickness b (mm) |

Bore d (mm) |

Cutting angle a |

Back angle β |

T-type | Positioning hole |

Number of teeth z |

|

|

|

|

|

|

|

|

|

| D(mm) | B-B1(mm) | b(mm) | d(mm) | α | β | T-type | positioning hole N°/A/L | Z |

| 105 | 2.2-1.3 | 1.5 | 40 | 20 | 15 | ATB | 20 | |

| 105 | 3.0-2.4 | 2.0 | 40 | 20 | 15 | ATB | 20 | |

| 130 | 2.2-1.2 | 1.5 | 40 | 20 | 15 | ATB | 20 | |

| 130 | 3.0-2.4 | 2.2 | 40 | 20 | 15 | ATB | 20 | |

| 150 | 2.2-1.4 | 1.5 | 40 | 20 | 15 | ATB | 24 | |

| 150 | 3.0-2.4 | 2.2 | 40 | 20 | 15 | ATB | 24 | |

| 160 | 2.2-1.4 | 1.5 | 40 | 20 | 15 | ATB | 24 | |

| 160 | 3.0-2.4 | 2.2 | 40 | 20 | 15 | ATB | 24 | |

| 180 | 2.2-1.8 | 1.6 | 40 | 20 | 15 | ATB | 36 | |

| 180 | 3.0-2.4 | 2.2 | 40 | 20 | 15 | ATB | 36 | |

| 212 | 2.4-1.3 | 1.4 | 50 | 20 | 15 | ATB | 36 | |

| 212 | 3.2-2.5 | 2.5 | 40 | 20 | 15 | ATB | 36 | |

| 230 | 2.4-1.6 | 1.6 | 40 | 20 | 15 | ATB | 36 | |

| 230 | 3.2-2.6 | 1.6 | 40 | 20 | 15 | ATB | 36 | |

| 255 | 2.6-2.0 | 1.9 | 40 | 20 | 15 | ATB | 36 | |

| 255 | 3.2-2.8 | 2.5 | 40 | 20 | 15 | ATB | 36 | |

| 280 | 2.8-2.2 | 2.1 | 50 | 20 | 15 | ATB | 36 | |

| 280 | 3.2-3.0 | 2.5 | 50 | 20 | 15 | ATB | 36 | |

| 305 | 2.8-2.2 | 2.2 | 50 | 20 | 15 | ATB | 36 | |

| 305 | 3.2-3.0 | 2.5 | 50 | 20 | 15 | ATB | 36 | |

| 320 | 2.8-2.6 | 2.2 | 50 | 20 | 15 | ATB | 36 | |

| 320 | 3.4-3.0 | 2.7 | 50 | 20 | 15 | ATB | 36 | |

| 355 | 3.4-2.8 | 2.5 | 50 | 20 | 15 | ATB | 36 | |

| 355 | 4.0-3.6 | 2.8 | 50 | 20 | 15 | ATB | 36 | |

| 380 | 3.6-3.0 | 2.6 | 60 | 20 | 15 | ATB | 36 | |

| 380 | 4.4-3.8 | 3.0 | 60 | 20 | 15 | ATB | 36 | |

| 405 | 3.6-3.0 | 2.7 | 60 | 20 | 15 | ATB | 40 | |

| 405 | 4.4-3.8 | 3.2 | 60 | 20 | 15 | ATB | 40 | |

| 455 | 4.0-3.4 | 2.8 | 60 | 20 | 15 | ATB | 40+6 | |

| 455 | 4.8-3.9 | 3.2 | 60 | 20 | 15 | ATB | 40+6 | |

| 480 | 4.0-3.4 | 2.8 | 60 | 20 | 15 | ATB | 42+6 | |

| 480 | 4.6-4.2 | 3.2 | 60 | 20 | 15 | ATB | 42+6 | |

| 500 | 4.2-3.6 | 3.0 | 70 | 20 | 15 | ATB | 42+6 | |

| 500 | 5.0-4.4 | 3.4 | 70 | 20 | 15 | ATB | 42+6 | |

| 550 | 4.4-3.8 | 3.6 | 70 | 20 | 15 | ATB | 44+8 | |

| 550 | 5.2-4.5 | 4.4 | 70 | 20 | 15 | ATB | 44+8 | |

| 600 | 5.5-4.2 | 3.8 | 70 | 20 | 15 | ATB | 48+8 | |

| 600 | 6.0-5.6 | 4.2 | 70 | 20 | 15 | ATB | 48+8 | |

| 650 | 6.0-4.8 | 3.8 | 70 | 20 | 15 | ATB | 48+8 | |

| 700 | 6.0-5.0 | 4.5 | 30 | 20 | 15 | ATB | 52+8 | |

| Divided into domestic steel plate and imported steel plate | ||||||||

| Remarks:Other specifications can be customized as reaquested. OEM and ODM services provided | ||||||||