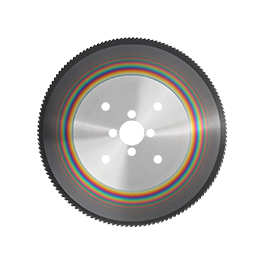

Tube Cutting Flying Saw with PVD Coating

Material:Tubes with small welding ribs or tubes without internal welding ribsMachine:single or twin flying sawSugges

Material: Tubes with small welding ribs or tubes without internal welding ribs

Machine: single or twin flying saw

Suggested speed: V=200-600m/min.

Tip: TCT (+PVD coating)

Advantages: high production line speed, smooth end surface, no burrs, long service life.

|

Outer Diameter D(mm) |

Tooth Width B(mm) |

Body Thickness b(mm) |

Bore d(mm) |

Number of Teeth z | |||

|

|

|

|

| |||

| D(mm) | B(mm) | b(mm) | d(mm) | Z | |||

| 350 | 3.2 | 2.7 | 50 | 100 | |||

| 110 | |||||||

| 120 | |||||||

| 140 | |||||||

| 400 | 3.6 | 3.2 | 40/50/80 | 110 | |||

| 120 | |||||||

| 130 | |||||||

| 140 | |||||||

| 450 | 3.6 | 3.2 | 50 | 120 | |||

| 130 | |||||||

| 140 | |||||||

| 160 | |||||||

| 500 | 3.6 | 3.2 | 50/80/90 | 120 | |||

| 130 | |||||||

| 140 | |||||||

| 160 | |||||||

| 525 | 3.6 | 3.2 | 50/80/90 | 140 | |||

| 160 | |||||||

| 180 | |||||||

| 550 | 3.6 | 3.2 | 50/80/90/140 | 120 | |||

| 140 | |||||||

| 160 | |||||||

| 170 | |||||||

| 600 | 3.6 | 3.2 | 50/80/90/140 | 120 | |||

| 140 | |||||||

| 170 | |||||||

| 180 | |||||||

| 620 | 3.6 | 3.2 | 50/140 | 150 | |||

| 170 | |||||||

| 630 | 3.6 | 3.2 | 50/80 | 120 | |||

| 140 | |||||||

| 160 | |||||||

| 180 | |||||||

| 200 | |||||||

| 650 | 3.6 | 3.2 | 50/80 | 120 | |||

| 140 | |||||||

| 160 | |||||||

| 180 | |||||||

| 200 | |||||||

| 690 | 3.8 | 3.3 | 50/80 | 140 | |||

| 150 | |||||||

| 170 | |||||||

| d | positioning hole N°x A x L | ||||||

| 40 | 4/16/80+4/12/90 | ||||||

| 50 | 4/16/80+4/13/90 | ||||||

| 80 | 4/23/120 | ||||||

| 90 | 3/12.5/160 | ||||||

| 140 | 4/17.5/170 | ||||||

| Remarks:Other specifications can be customized as reaquested. OEM and ODM services provided | |||||||

TCT HM AND CERMET(STEEL & STAINLESS)

TCT saw blades(Steel & Stainless) in Carbide and Cermet, suitable for every customer application. Hard Metal (HM) is obtained through the synthesizing of tungsten carbide dust, titanium and tantalum, mixed with cobalt dust as a binder. The finely mixed materials are heated to 1500°C and pressed, in order to obtain very thin molecules to form a single homogeneous solid. The main features of HM are to maintain hardness and wear resistance even at the highest operating temperatures developed in the most difficult applications.

Cermet is a special product obtained through synthesizing ceramic dust, silicon carbides and metal oxides which are resistant to the highest temperatures, such as: chrome, cobalt, nickel, titanium, aluminium and tungsten. Cermet is a material with a hardness between silicon carbide and diamond. It is very resistant to high cutting temperatures and is able to withstand extremely high machining rates. Cermet generates an excellent surface finish on the cut material and an extra-long tool life.